Sintering Molybdenum Bar - Hot Selling Best Price 99.95%Min. Purity Molybdenum Crucible /Pot For Melting – HSG Metal

Sintering Molybdenum Bar - Hot Selling Best Price 99.95%Min. Purity Molybdenum Crucible /Pot For Melting – HSG Metal Detail:

Product Parameters

| Item name | Hot Selling Best Price 99.95%min. Purity Molybdenum Crucible /Pot for Melting |

| Purity | 99.97% Mo |

| Working temperature | 1300-1400Centigrade:Mo1 2000 Centigrade:TZM 1700-1900Centigrade: MLa |

| Delivery time | 10-15 days |

| Other Material | TZM, MHC, MO-W, MO-RE, MO-LA,Mo1 |

| Dimension & Cubage | According to your needs or drawings |

| Surface | Finish turning, Grinding |

| Density | 1.Sintering molybdenum crucible Density: >9.8g/cm3; 2.Forging molybdenum crucible Density: >10.1g/cm3 |

| MOQ | 1pcs |

| Condition | 1.Molybdenum rod or ingot 2.Lathe machine 3.CNC machining center 4.Surface treatment |

| Application | 1.smelting of rare earth metals2.heating elements of induction furnace3. solar energy and sapphire. |

| Product can be produced according to your drawing. | |

Size and Tolerance

|

Forge molybdenum crucible |

|||||||

|

Purity |

Density |

Sizes |

Tolerance |

Wall thickness |

roughness |

||

|

99.95% |

≥10.1g/ cm3 |

Dia(mm): |

Height(mm): |

Dia: |

Height: |

4-20mm |

Ra=1.6mic |

|

Sinter molybdenum crucible |

|||||||

|

Purity |

Density |

Sizes |

Tolerance |

Wall thickness |

roughness |

||

|

99.95% |

≥9.8g/ cm3 |

Dia(mm): |

Height(mm): |

Dia: |

Height: |

8-20mm |

Ra=1.6mic |

|

Sintering and Mechining |

|||||||

|

Purity |

Density |

Sizes |

Tolerance |

Wall thickness |

roughness |

||

|

99.95% |

≥9.8g/ cm3 |

Dia(mm): |

Height(mm): |

Dia: |

Height: |

8-20mm |

Ra=1.6mic |

Chemical composition

| Purity(%) | Ag | Ni | P | Cu | Pb | N |

| <0.0001 | <0.0005 | <0.001 | <0.0001 | <0.0001 | <0.002 | |

| Si | Mg | Ca | Sn | Ba | Cd | |

| <0.001 | <0.0001 | <0.001 | <0.0001 | <0.0003 | <0.001 | |

| Na | C | Fe | O | H | Mo | |

| <0.0024 | <0.0033 | <0.0016 | <0.0062 | <0.0006 | >99.97 |

Feature

1. High density

2. Good corrosion resistance

3. The surface roughness of tooled crucibles does not exceed Rz 6.3

4. The use temperature below 2450ºC in vacuum or deoxidize atmosphere

5. Manufactured based on customers’ requirement

Application

With a high corrosion resistance to most acids and many molten materials such as glass or metals.

Molybdenum crucibles are ideal for the metallurgy, mechanism, and rare earth smelting industries.

They can withstand vacuum thermal evaporation, nuclear fuel sintering, and capacitor sintering.

Molybdenum crucibles are also seeing an increased use in the growing high technology industry and in crystalloid materials.

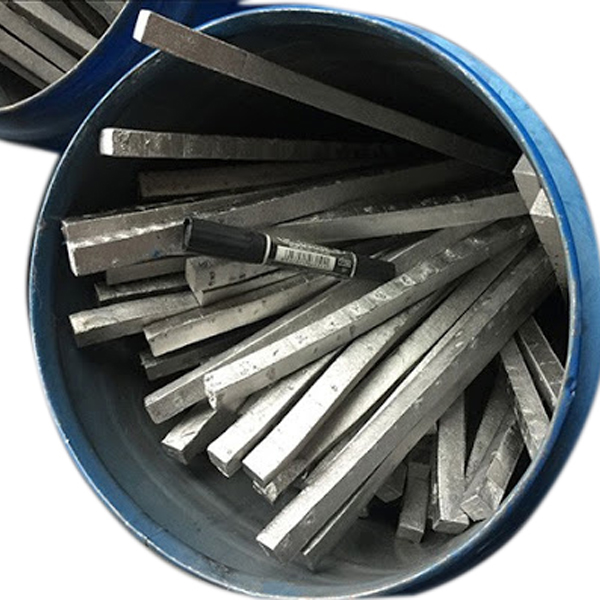

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for Sintering Molybdenum Bar - Hot Selling Best Price 99.95%Min. Purity Molybdenum Crucible /Pot For Melting – HSG Metal , The product will supply to all over the world, such as: Zimbabwe, Nepal, Lithuania, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.