Short Lead Time for Molybdenum Rods Manufacturers - 0.18mm EDM Molybdenum PureS Type for CNC High Speed Wire Cut WEDM Machine – HSG Metal

Short Lead Time for Molybdenum Rods Manufacturers - 0.18mm EDM Molybdenum PureS Type for CNC High Speed Wire Cut WEDM Machine – HSG Metal Detail:

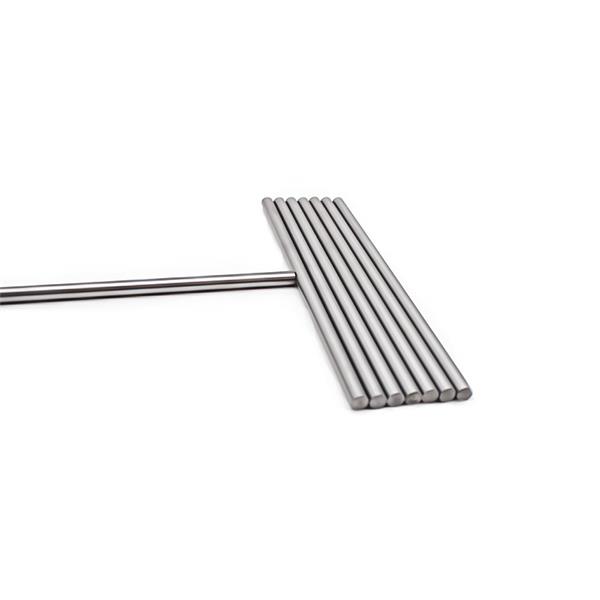

Molybdenum wire advantage

1. Molybdenum wire high pricision,line diameter tolerance control at less than 0 to 0.002mm

2. The ratio of breaking wire low,processing rate is high,good performance and good price.

3. Can finish the stable long time continuous processing.

Products Description

Edm molybdenum Moly wire 0.18mm 0.25mm

Molybdenum wire(spray moly wire)is mainly used for auto parts spraying,such as piston ring,synchronizer rings,shift elements,etc.Molybdenum spray wire is also used in repairs of machine parts,such as bearing,bearing shells,shafts,etc.

Specifications

| Specifications for molybdenum wire: | ||

| Molybdenum Wire Types | Diameter (inch) | Tolerance (%) |

| Molybdenum Wire for EDM | 0.0024″ ~ 0.01″ | ±3% wt |

| Molybdenum Spray Wire | 1/16″ ~ 1/8″ | ±1% to 3% wt |

| Molybdenum Wire | 0.002″ ~ 0.08″ | ±3% wt |

| Molybdenum Wire(clean) | 0.006″ ~ 0.04″ | ±3% wt |

Black Molybdenum Wire ( Coated with graphite) Molybdenum Wire ( Uncoated)

|

Grade |

Mo-1 |

|

| The impurity content is not more than 0.01% |

Fe |

0.01 |

|

Ni |

0.005 |

|

|

Al |

0.002 |

|

|

Si |

0.01 |

|

|

Mg |

0.005 |

|

|

C |

0.01 |

|

|

N |

0.003 |

|

|

O |

0.008 |

|

Feature of molybdenum wire for cnc edm cutting

• High melting point, Low density and Thermal coefficients

• Good thermal conductivity properties and Resistance of high-temperature

• High tensile strength and Low elongation

• Good stability and High precision of cutting

• High speed and Long stable time of processing

• Long lifetime and Non-poisonous

Application of molybdenum wire for cnc edm cutting

• Electric light source, Electrode

• Heating elements, High-temperature components

• Wire-electrode cutting

• Spraying for auto parts

Application and Use

Molybdenum edm wire is widely used for petrochemical, aerospace, automotive industry, sapphire growing, glass and ceramics, furnace construction and heat treating, electric light source, electro vacuum, power industry, rare earth metal industry, quartz industry, ion implantation, LED industry, solar energy, heat sinks and electronic packaging materials and so on.

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for Short Lead Time for Molybdenum Rods Manufacturers - 0.18mm EDM Molybdenum PureS Type for CNC High Speed Wire Cut WEDM Machine – HSG Metal , The product will supply to all over the world, such as: Nicaragua, The Swiss, Algeria, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!