OEM/ODM Factory Tantalum Metal Sheet - High Pure 99.95% For Atomic Energy Industry Good Plasticity Wear Resistance Tantalum Rod/Bar Tantalum Products – HSG Metal

OEM/ODM Factory Tantalum Metal Sheet - High Pure 99.95% For Atomic Energy Industry Good Plasticity Wear Resistance Tantalum Rod/Bar Tantalum Products – HSG Metal Detail:

Product Parameters

| Product Name | 99.95% Tantalum ingot bar buyers ro5400 tantalum price |

| Purity | 99.95% min |

| Grade | R05200, R05400, R05252, RO5255, R05240 |

| Standard | ASTM B365 |

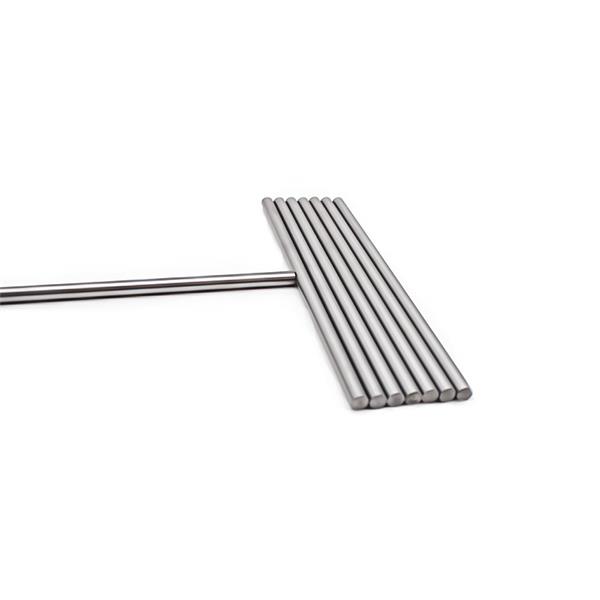

| Size | Dia(1~25)xMax3000mm |

| Condition | 1.Hot-rolled/Cold-rolled; 2.Alkaline Cleaning; 3.Electrolytic Polish; 4.Machining, grinding; 5.Stress relief annealing. |

| Mechanical property(Annealed) | Grade; Tensile strength min;Yield strength min; Elongation min, % |

| (UNS), psi (MPa), psi(MPa)(2%), (1in. gage length) | |

| (RO5200, RO5400), 30000 (207), 20000 (138), 20 | |

| Ta-10W (RO5255), 70000 (482), 60000 (414),15 | |

| Ta-2.5W (RO5252), 40000 (276), 30000 (207), 20 | |

| Ta-40Nb (RO5240), 35000 (241), 20000 (138), 25 | |

| Customized products | According to drawing, Special requirements to be agreed upon by the supplier and buyer. |

Specification

| Diameter | Diameter Tolerance | Length | Tolerance | |||

| forging rod | Extruded Rods | rolling rod | ground rod | |||

| 3.0-4.5 | ±0.05 | - | ±0.05 | - | 500-1500 | + 5 |

| >4.5-6.5 | ±0.10 | - | ±0.10 | - | 500-1500 | + 5 |

| >6.5-10.0 | ±0.15 | - | ±0.15 | - | 400-1500 | + 5 |

| >10-16 | ±0.20 | - | ±0.20 | - | 300-1200 | + 5 |

| >16-18 | ±1.0 | - | - | ±0.30 | 200-2000 | + 20 |

| >18-25 | ±1.5 | ±1.0 | - | ±0.40 | 200-2000 | + 20 |

| >25-40 | ±2.0 | ±1.5 | - | ±0.50 | 150-4000 | + 20 |

| >40-50 | ±2.5 | ±2.0 | - | ±0.60 | 100-3000 | + 20 |

| >50-65 | ±3.0 | ±2.0 | - | ±0.80 | 100-1500 | + 20 |

TableⅠChemical Composition of Tantalum Rod

| Chemistry ppm | ||||||||||||

| Description | Chief component | Impurities maximum | ||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N | |

| Ta1 | Remainder | 300 | 40 | 30 | 20 | 40 | 40 | 20 | 150 | 40 | 15 | 20 |

| Ta2 | Remainder | 800 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| TaNb3 | Remainder | <35000 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| TaNb20 | Remainder | 170000- 230000 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| Ta2.5W | Remainder | 400 | 50 | 30 | 20 | 30000 | 60 | 20 | 150 | 50 | 15 | 60 |

| Ta10W | Remainder | 400 | 50 | 30 | 20 | 110000 | 60 | 20 | 150 | 50 | 15 | 60 |

Table Ⅱ Permissible Variations in Diameter for Tantalum Rods

| Diameter, inch (mm) | Tolerance, +/-inch (mm) |

| 0.125~0.187 excl (3.175~4.750) | 0.003 (0.076) |

| 0.187~0.375 excl (4.750~9.525) | 0.004 (0.102) |

| 0.375~0.500 excl (9.525~12.70) | 0.005 (0.127) |

| 0.500~0.625 excl (12.70~15.88) | 0.007 (0.178) |

| 0.625~0.750 excl (15.88~19.05) | 0.008 (0.203) |

| 0.750~1.000 excl (19.05~25.40) | 0.010 (0.254) |

| 1.000~1.500 excl (25.40~38.10) | 0.015 (0.381) |

| 1.500~2.000 excl (38.10~50.80) | 0.020 (0.508) |

| 2.000~2.500 excl (50.80~63.50) | 0.030 (0.762) |

Application

Capacitors; surgical implants and instruments; ink jet nozzles.

Used in laboratory equipment.

Used as a substitute for platinum.

Used in manufacturing super alloys and electron-beam melting.

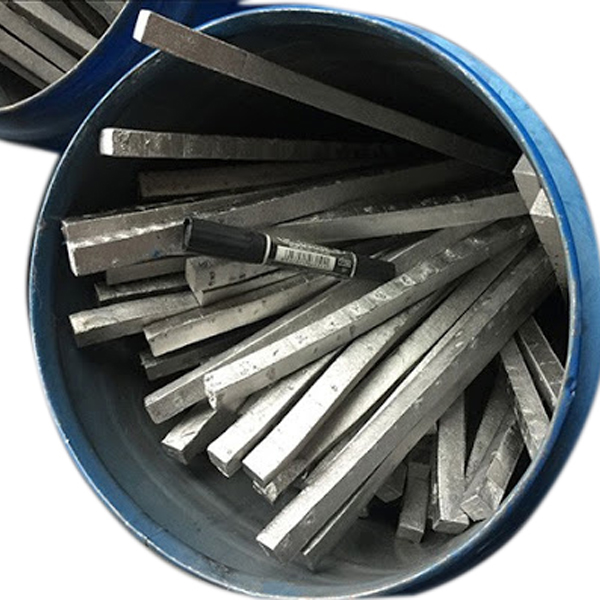

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for OEM/ODM Factory Tantalum Metal Sheet - High Pure 99.95% For Atomic Energy Industry Good Plasticity Wear Resistance Tantalum Rod/Bar Tantalum Products – HSG Metal , The product will supply to all over the world, such as: Cambodia, Oslo, Czech, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Write your message here and send it to us