OEM/ODM China Ingot Indium - Tungsten Target – HSG Metal

OEM/ODM China Ingot Indium - Tungsten Target – HSG Metal Detail:

Product parameters

| Product Name | Tungsten(W)sputtering target |

| Grade | W1 |

| Available Purity(%) | 99.5%,99.8%,99.9%,99.95%,99.99% |

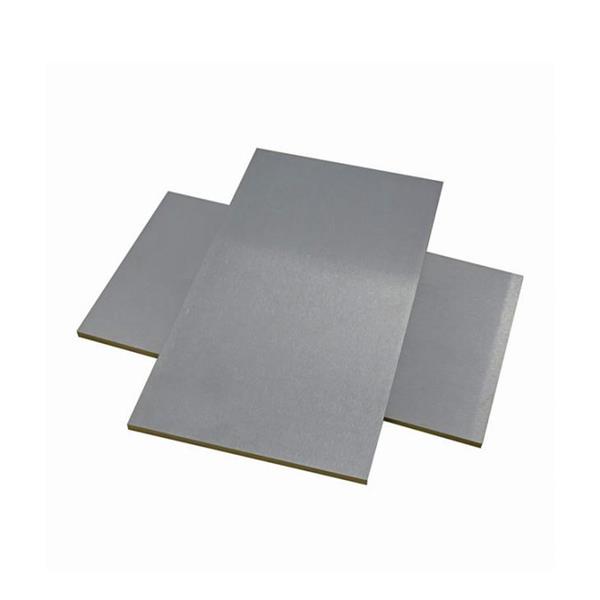

| Shape: | Plate, round, rotary, pipe/tube |

| Specification | As customers demands |

| Standard | ASTM B760-07,GB/T 3875-06 |

| Density | ≥19.3g/cm3 |

| Melting point | 3410°C |

| Atomic volume | 9.53 cm3/mol |

| Temperature coefficient of resistance | 0.00482 I/℃ |

| Sublimation heat | 847.8 kJ/mol(25℃) |

| Latent heat of melting | 40.13±6.67kJ/mol |

| State | Planar tungsten target,Rotating tungsten target,Round tungsten target |

| surface state | Polish or alkali wash |

| Workmanship | Tungsten billet (raw material)- Test- Hot rolling-Leveling and annealing-Alkali wash-Polish-Test-Packing |

The sprayed and sintered tungsten target has the characteristics of 99% density or higher, the average transparent texture diameter is 100um or less, the oxygen content is 20ppm or less, and the deflection force is about 500Mpa; it improves the production of unprocessed metal powder To improve the sintering ability, the cost of the tungsten target can be stabilized at a low price. The sintered tungsten target has a high density, has a high-level transparent frame that cannot be achieved by the traditional pressing and sintering method, and significantly improves the deflection angle, so that the particulate matter is significantly reduced.

Advantage

(1) Smooth surface without pore,scratch and other imperfection

(2) Grinding or lathing edge, no cutting marks

(3) Unbeatable lerel of material purity

(4) High ductility

(5) Homogeneous micro trucalture

(6) Laser marking for your special Item with name, brand, purity size and so on

(7) Every pcs of sputtering targets from the powder materials item&number, mixing workers,outgas and HIP time,machining person and packing details are all made ourselves.

All of those step can promise you once a new sputtering target or method is created , it could be copied and kept to support a stabel quality products.

Other dvantage

High quality materials

(1) 100 % density = 19.35 g/cm³

(2) Dimensional stability

(3) Enhanced mechanical properties

(4) Uniform grain size distribution

(5) Small grain sizes

Appalachian

Tungsten target material is mainly used in aerospace, rare earth smelting, electric light source, chemical equipment, medical equipment, metallurgical machinery, smelting equipment, petroleum and other fields.

Product detail pictures:

Related Product Guide:

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for OEM/ODM China Ingot Indium - Tungsten Target – HSG Metal , The product will supply to all over the world, such as: Kazakhstan, Salt Lake City, Singapore, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!