Manufacturer for Ruthenium Powder For Coating - Factory Direct Supply High Quality Ruthenium Pellet, Ruthenium Metal Ingot, Ruthenium Ingot – HSG Metal

Manufacturer for Ruthenium Powder For Coating - Factory Direct Supply High Quality Ruthenium Pellet, Ruthenium Metal Ingot, Ruthenium Ingot – HSG Metal Detail:

Chemical composition and specifications

|

Ruthenium Pellet |

|||||||

|

Main content: Ru 99.95% min (excluding gas element) |

|||||||

|

Impurities(%) |

|||||||

| Pd | Mg | Al | Si | Os | Ag | Ca | Pb |

| <0.0005 | <0.0005 | <0.0005 | <0.0030 | <0.0100 | <0.0005 | <0.0005 | <0.0005 |

| Ti | V | Cr | Mn | Fe | Co | Ni | Bi |

| <0.0005 | <0.0005 | <0.0010 | <0.0005 | <0.0020 | <0.0005 | <0.0005 | <0.0010 |

| Cu | Zn | As | Zr | Mo | Cd | Sn | Se |

| <0.0005 | <0.0005 | <0.0005 | <0.0005 | <0.0005 | <0.0005 | <0.0005 | <0.0005 |

| Sb | Te | Pt | Rh | lr | Au | B | |

| <0.0005 | <0.0005 | <0.0005 | <0.0005 | <0.0005 | <0.0005 | <0.0005 | |

Product details

Symbol: Ru

Number: 44

Element category: Transition metal

CAS number: 7440-18-8

Density: 12,37 g/cm3

Hardness: 6,5

Melting point: 2334°C (4233.2°F)

Boiling point: 4150°C (7502°F)

Standard atomic weight: 101,07

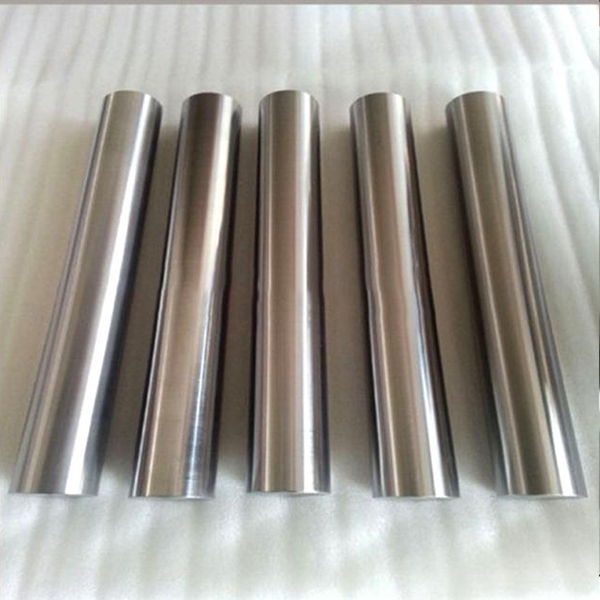

Size: Diameter 15~25mm, Height 10~25mm.Special size is available upon customers’ requirements.

Package: Sealed and filled with inert gas in plastic bags or plastic bottles inside steel drums.

Product features

Ruthenium resistor paste: electric conductance material (ruthenium, ruthenium dioxide acid bismuth, ruthenium lead acid, etc.) glass binder, the organic carrier and so on of the most widely used a resistor paste, with a wide range of resistance, low temperature coefficient of resistance, resistance with good reproducibility, and the advantages of good environmental stability, used to make high performance resistance and high reliable precision resistor network.

Application

Ruthenium pellet is often used as element additives for the manufacture of Ni-base superalloy in aviation and industrial gas turbine. Research has shown that, in the fourth generation of nickel base single crystal superalloys, the introduction of the new alloy elements Ru, which can improve the nickel-base superalloy liquidus temperature and increase the alloy’s high temperature creep properties and structural stability, resulting in the special “Ru effect” to improve overall performance and efficiency of the engine.

Product detail pictures:

Related Product Guide:

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for Manufacturer for Ruthenium Powder For Coating - Factory Direct Supply High Quality Ruthenium Pellet, Ruthenium Metal Ingot, Ruthenium Ingot – HSG Metal , The product will supply to all over the world, such as: Denmark, Singapore, Norway, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.