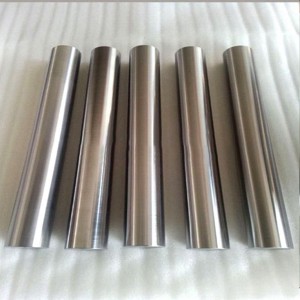

High Pure 99.95% For Atomic Energy Industry Good Plasticity Wear Resistance Tantalum Rod/Bar Tantalum Products

Product Parameters

| Product Name | 99.95% Tantalum ingot bar buyers ro5400 tantalum price |

| Purity | 99.95% min |

| Grade | R05200, R05400, R05252, RO5255, R05240 |

| Standard | ASTM B365 |

| Size | Dia(1~25)xMax3000mm |

| Condition | 1.Hot-rolled/Cold-rolled; 2.Alkaline Cleaning; 3.Electrolytic Polish; 4.Machining, grinding; 5.Stress relief annealing. |

| Mechanical property(Annealed) |

Grade; Tensile strength min;Yield strength min; Elongation min, % |

| (UNS), psi (MPa), psi(MPa)(2%), (1in. gage length) | |

| (RO5200, RO5400), 30000 (207), 20000 (138), 20 | |

| Ta-10W (RO5255), 70000 (482), 60000 (414),15 | |

| Ta-2.5W (RO5252), 40000 (276), 30000 (207), 20 | |

| Ta-40Nb (RO5240), 35000 (241), 20000 (138), 25 | |

| Customized products | According to drawing, Special requirements to be agreed upon by the supplier and buyer. |

Specification

| Diameter | Diameter Tolerance | Length | Tolerance | |||

| forging rod | Extruded Rods | rolling rod | ground rod | |||

| 3.0-4.5 | ±0.05 | - | ±0.05 | - | 500-1500 | + 5 |

| >4.5-6.5 | ±0.10 | - | ±0.10 | - | 500-1500 | + 5 |

| >6.5-10.0 | ±0.15 | - | ±0.15 | - | 400-1500 | + 5 |

| >10-16 | ±0.20 | - | ±0.20 | - | 300-1200 | + 5 |

| >16-18 | ±1.0 | - | - | ±0.30 | 200-2000 | + 20 |

| >18-25 | ±1.5 | ±1.0 | - | ±0.40 | 200-2000 | + 20 |

| >25-40 | ±2.0 | ±1.5 | - | ±0.50 | 150-4000 | + 20 |

| >40-50 | ±2.5 | ±2.0 | - | ±0.60 | 100-3000 | + 20 |

| >50-65 | ±3.0 | ±2.0 | - | ±0.80 | 100-1500 | + 20 |

TableⅠChemical Composition of Tantalum Rod

| Chemistry ppm | ||||||||||||

| Description | Chief component | Impurities maximum | ||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N | |

| Ta1 | Remainder | 300 | 40 | 30 | 20 | 40 | 40 | 20 | 150 | 40 | 15 | 20 |

| Ta2 | Remainder | 800 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| TaNb3 | Remainder | <35000 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| TaNb20 | Remainder | 170000- 230000 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| Ta2.5W | Remainder | 400 | 50 | 30 | 20 | 30000 | 60 | 20 | 150 | 50 | 15 | 60 |

| Ta10W | Remainder | 400 | 50 | 30 | 20 | 110000 | 60 | 20 | 150 | 50 | 15 | 60 |

Table Ⅱ Permissible Variations in Diameter for Tantalum Rods

| Diameter, inch (mm) | Tolerance, +/-inch (mm) |

| 0.125~0.187 excl (3.175~4.750) | 0.003 (0.076) |

| 0.187~0.375 excl (4.750~9.525) | 0.004 (0.102) |

| 0.375~0.500 excl (9.525~12.70) | 0.005 (0.127) |

| 0.500~0.625 excl (12.70~15.88) | 0.007 (0.178) |

| 0.625~0.750 excl (15.88~19.05) | 0.008 (0.203) |

| 0.750~1.000 excl (19.05~25.40) | 0.010 (0.254) |

| 1.000~1.500 excl (25.40~38.10) | 0.015 (0.381) |

| 1.500~2.000 excl (38.10~50.80) | 0.020 (0.508) |

| 2.000~2.500 excl (50.80~63.50) | 0.030 (0.762) |

Application

Capacitors; surgical implants and instruments; ink jet nozzles.

Used in laboratory equipment.

Used as a substitute for platinum.

Used in manufacturing super alloys and electron-beam melting.

Write your message here and send it to us