Ferro Molybdenum Manufacturing Process - High Quality Price Per Kg Mo1 Mo2 Pure Molybdenum Cube Block For Sale – HSG Metal

Ferro Molybdenum Manufacturing Process - High Quality Price Per Kg Mo1 Mo2 Pure Molybdenum Cube Block For Sale – HSG Metal Detail:

Product Parameters

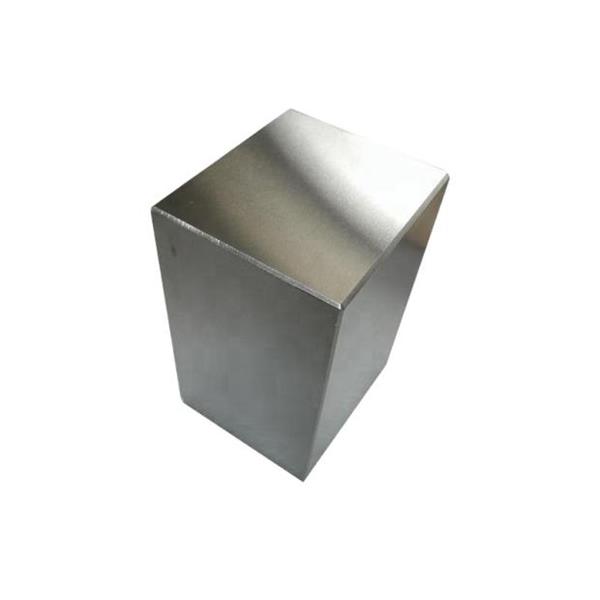

| Product name | Pure molybdenum cube / molybdenum block for industry |

| Grade | Mo1 Mo2 TZM |

| Type | cube, block, ignot,lump |

| Surface | Polish/grinding/chemical wash |

| Density | 10.2g/cc |

| Processing | Rolling, Forging, Sintering |

| Standard | ASTM B 386-2003, GB 3876-2007, GB 3877-2006 |

| Size | Thickness: min0.01mmWidth: max 650mm |

| Popular size | 10*10*10mm / 20*20*20mm / 46*46*46 mm / 58*58*58mm |

Chemical requirements

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Cd | Ca | P |

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 |

| Element | C | O | N | Sb | Sn | |||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 |

Feature

The purity of molybdenum sheet is over 99.95%. The high-temperature rare-earth element added molybdenum sheet is also with high purity above 99%;

The density of molybdenum sheet is more than or equals to 10.1g/cm3;

The flatness is no more than 3%;

It has good performances of high strength, uniform internal organization and good resistance to high temperature creep;

The surface of molybdenum may present silver gray metallic luster after chemical cleaning.

Application

Molybdenum are used for producing molybdenum electrodes, heating elements, heat shields, sintering trays, sintering boats, stacking sheets, base plates, sputtering targets, crucibles in electronic and vacuum applications;

Widely used for producing reflecting screen and cover inside sapphire crystal growth furnace, as well as reflecting screen, heating tape and connection inside vacuum furnace;

Molybdenum are also applied in sputtering target of materials plasma coating, high temperature resistant boat, etc.

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Ferro Molybdenum Manufacturing Process - High Quality Price Per Kg Mo1 Mo2 Pure Molybdenum Cube Block For Sale – HSG Metal , The product will supply to all over the world, such as: Malaysia, San Francisco, belarus, Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!