Factory Cheap Hot Ferro Molybdeen Poeder - China Ferro Molybdenum Factory Supply Quality Low Carbon Femo Femo60 Ferro Molybdenum Price – HSG Metal

Factory Cheap Hot Ferro Molybdeen Poeder - China Ferro Molybdenum Factory Supply Quality Low Carbon Femo Femo60 Ferro Molybdenum Price – HSG Metal Detail:

Chemical Composition

| FeMo composition (%) | ||||||

|

Grade |

Mo |

Si |

S |

P |

C |

Cu |

|

FeMo70 |

65-75 |

2 |

0.08 |

0.05 |

0.1 |

0.5 |

|

FeMo60-A |

60-65 |

1 |

0.08 |

0.04 |

0.1 |

0.5 |

|

FeMo60-B |

60-65 |

1.5 |

0.1 |

0.05 |

0.1 |

0.5 |

|

FeMo60-C |

60-65 |

2 |

0.15 |

0.05 |

0.15 |

1 |

|

FeMo55-A |

55-60 |

1 |

0.1 |

0.08 |

0.15 |

0.5 |

|

FeMo55-B |

55-60 |

1.5 |

0.15 |

0.1 |

0.2 |

0.5 |

Products Description

Ferro Molybdenum70 is mainly used to add molybdenum to steel in steel making. Molybdenum is mixed with other alloy elements to be widely used to make stainless steel, heat resistant steel, acid-resistant steel and tool steel. And it is also used to produce the alloy which has especially physical properties. To add molybdenum to iron casting can improve strength and abrasion resistance.

Properties

To add molybdenum to steel makes steel to have uniform fine-grained structure and improve hardenability of steel to eliminate temper brittleness. Molybdenum can substitute a volume of tungsten in high speed steel.

Other parameters

Standard: (GB/T3649-1987)

Shape: Ferro Molybdenum, 70 should be delivered in lump or powder.

Size: Its size range is from 10 to 150mm. the quality of this product whose particle size range is less than 10mm×10mm should not exceed 5% of the total quality of this product.

Package: 100kg per iron bucket or 1MT pp bag

Application

Ferro Molybdenum has long been used as a typical additive for steel, giving iron the properties of being hard, having excellent impact strength, stickiness, and being hard to deform, and playing an important role in the formation of social infrastructure such as skyscrapers and highways.

It is also used in fields that require higher functionality and quality, such as thin sheets for automobiles and special composite materials for aircraft.

It is also widely used as a desulfurization catalyst during petroleum refining and as a catalyst / additive for the chemical industry, contributing to environmental protection and the development of the chemical industry.

Today, molybdenum is attracting attention not only for conventional applications but also as a new material for communication equipment and electronic components.

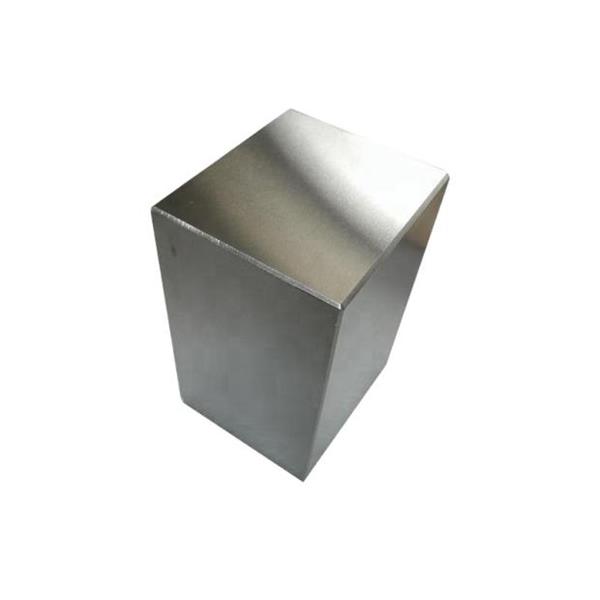

Product detail pictures:

Related Product Guide:

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Factory Cheap Hot Ferro Molybdeen Poeder - China Ferro Molybdenum Factory Supply Quality Low Carbon Femo Femo60 Ferro Molybdenum Price – HSG Metal , The product will supply to all over the world, such as: Surabaya, Myanmar, Borussia Dortmund, We've got won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!