Best quality Tantalum Oxide Powder - High Pure 99.95% For Atomic Energy Industry Good Plasticity Wear Resistance Tantalum Rod/Bar Tantalum Products – HSG Metal

Best quality Tantalum Oxide Powder - High Pure 99.95% For Atomic Energy Industry Good Plasticity Wear Resistance Tantalum Rod/Bar Tantalum Products – HSG Metal Detail:

Product Parameters

| Product Name | 99.95% Tantalum ingot bar buyers ro5400 tantalum price |

| Purity | 99.95% min |

| Grade | R05200, R05400, R05252, RO5255, R05240 |

| Standard | ASTM B365 |

| Size | Dia(1~25)xMax3000mm |

| Condition | 1.Hot-rolled/Cold-rolled; 2.Alkaline Cleaning; 3.Electrolytic Polish; 4.Machining, grinding; 5.Stress relief annealing. |

| Mechanical property(Annealed) | Grade; Tensile strength min;Yield strength min; Elongation min, % |

| (UNS), psi (MPa), psi(MPa)(2%), (1in. gage length) | |

| (RO5200, RO5400), 30000 (207), 20000 (138), 20 | |

| Ta-10W (RO5255), 70000 (482), 60000 (414),15 | |

| Ta-2.5W (RO5252), 40000 (276), 30000 (207), 20 | |

| Ta-40Nb (RO5240), 35000 (241), 20000 (138), 25 | |

| Customized products | According to drawing, Special requirements to be agreed upon by the supplier and buyer. |

Specification

| Diameter | Diameter Tolerance | Length | Tolerance | |||

| forging rod | Extruded Rods | rolling rod | ground rod | |||

| 3.0-4.5 | ±0.05 | - | ±0.05 | - | 500-1500 | + 5 |

| >4.5-6.5 | ±0.10 | - | ±0.10 | - | 500-1500 | + 5 |

| >6.5-10.0 | ±0.15 | - | ±0.15 | - | 400-1500 | + 5 |

| >10-16 | ±0.20 | - | ±0.20 | - | 300-1200 | + 5 |

| >16-18 | ±1.0 | - | - | ±0.30 | 200-2000 | + 20 |

| >18-25 | ±1.5 | ±1.0 | - | ±0.40 | 200-2000 | + 20 |

| >25-40 | ±2.0 | ±1.5 | - | ±0.50 | 150-4000 | + 20 |

| >40-50 | ±2.5 | ±2.0 | - | ±0.60 | 100-3000 | + 20 |

| >50-65 | ±3.0 | ±2.0 | - | ±0.80 | 100-1500 | + 20 |

TableⅠChemical Composition of Tantalum Rod

| Chemistry ppm | ||||||||||||

| Description | Chief component | Impurities maximum | ||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N | |

| Ta1 | Remainder | 300 | 40 | 30 | 20 | 40 | 40 | 20 | 150 | 40 | 15 | 20 |

| Ta2 | Remainder | 800 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| TaNb3 | Remainder | <35000 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| TaNb20 | Remainder | 170000- 230000 | 100 | 100 | 50 | 200 | 200 | 50 | 200 | 100 | 15 | 100 |

| Ta2.5W | Remainder | 400 | 50 | 30 | 20 | 30000 | 60 | 20 | 150 | 50 | 15 | 60 |

| Ta10W | Remainder | 400 | 50 | 30 | 20 | 110000 | 60 | 20 | 150 | 50 | 15 | 60 |

Table Ⅱ Permissible Variations in Diameter for Tantalum Rods

| Diameter, inch (mm) | Tolerance, +/-inch (mm) |

| 0.125~0.187 excl (3.175~4.750) | 0.003 (0.076) |

| 0.187~0.375 excl (4.750~9.525) | 0.004 (0.102) |

| 0.375~0.500 excl (9.525~12.70) | 0.005 (0.127) |

| 0.500~0.625 excl (12.70~15.88) | 0.007 (0.178) |

| 0.625~0.750 excl (15.88~19.05) | 0.008 (0.203) |

| 0.750~1.000 excl (19.05~25.40) | 0.010 (0.254) |

| 1.000~1.500 excl (25.40~38.10) | 0.015 (0.381) |

| 1.500~2.000 excl (38.10~50.80) | 0.020 (0.508) |

| 2.000~2.500 excl (50.80~63.50) | 0.030 (0.762) |

Application

Capacitors; surgical implants and instruments; ink jet nozzles.

Used in laboratory equipment.

Used as a substitute for platinum.

Used in manufacturing super alloys and electron-beam melting.

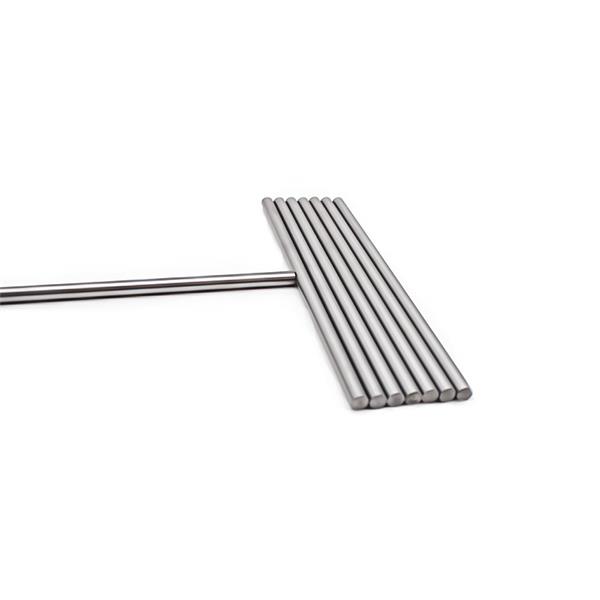

Product detail pictures:

Related Product Guide:

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for Best quality Tantalum Oxide Powder - High Pure 99.95% For Atomic Energy Industry Good Plasticity Wear Resistance Tantalum Rod/Bar Tantalum Products – HSG Metal , The product will supply to all over the world, such as: Tanzania, United Arab Emirates, Slovakia, We seriously promise that we provide all the customers with the best quality products, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

Write your message here and send it to us